A

Abrasive wear

Wear or texture change to an area of carpet that has been damaged by friction caused by rubbing or foot traffic.

Absorption

Process by which a substance or particle is drawn into the structure of another.

Acid dyeable nylon

Nylon polymer that has been modified chemically to make the fiber receive acid dyes. Acid dyeable yarns are available in different dye levels (light, medium and deep).

Acute Exposure

A short-term exposure to a substance or material (typically less than one day).

Acute Toxicity

In toxicology, an effect that is manifested rapidly (i.e., minutes, hours, or even a few days) after the exposure to a hazard; either the exposure that generates the response, or the response itself, can be called acute (compare with “Chronic”).

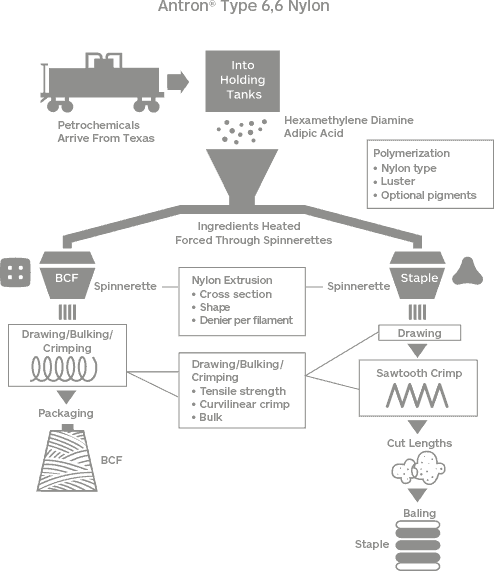

Adipic acid

A base ingredient in the production of Type 6,6 nylon. Adipic acid has a chain of six carbon atoms. It is reacted with hexamethylene diamine, which also has six carbon atoms, to polymerize Type 6,6 nylon.

Adsorbent

Material that is capable of the binding and collection of substances or particles on its surface without chemically altering them.

Aesthetics

Properties perceived by touch and sight, color

Affinity

The tendency for two elements or substances to combine chemically. An example is the affinity of acid dyes for nylon fiber.

Air-entangling (also known as intermingling, commingling or heathered)

A method of producing yarn by combining two or more BCF fibers together. Fibers are “locked” together via air jets at regular or irregular intervals. The process is used to obtain special effect yarn (i.e., mixing dye variants to get heather effects upon subsequent dyeing or combining different colors of solution dyed fiber). Various air-entangling processes exist making it possible to produce a wide range of aesthetics in finished yarns, from highly blended, near solid looks to yarns where individual colors are accented and color separation mimics that of plied yarns.

Airborne Particulates

Total suspended particulate matter found in the atmosphere as solid particles or liquid droplets. Chemical composition of particulates varies widely, depending on location and time of year. Sources of airborne particulates include dust, emissions from industrial processes, combustion products from the burning of wood and coal, combustion products associated with motor vehicle or non-road engine exhausts, and reactions to gases in the atmosphere.

Ambient Air

The surrounding air.

Amine end groups

The terminating (-NH2) group of a nylon polymer chain. Amine end groups provide dye sites for nylon (polyamide) fibers.

Antimicrobial

An agent that kills microbes.

Antistatic properties

Resisting the tendency to produce annoying static electric shocks in situations where friction of the foot tread builds up static in low-humidity conditions. Some nylon fibers introduce a conductive filament in the yarn bundle to conduct or dissipate static charges from the human body. Olefin fiber is inherently static-resistant, as it is similar to the surface of most shoe soles (only dissimilar surfaces rub to create a static charge). There are two basic methods for controlling the buildup of static in nylon carpets:

- Treating the carpet with a topical spray. This is not permanent and create a tendency for the carpet surface to soil.

- Adding a carbon composite nylon filament into the bundle of yarn to act as a dissipating rod carrying the static charge away from the person generating it.

ASTM (The American Society for Testing and Materials)

One of the largest voluntary standards development organizations in the world. ASTM is a not-for-profit organization that provides a forum for the development and publication of voluntary consensus standards for materials, products, systems and services.

Autoclave

(1) An oven-like apparatus for use in yarn heatsetting operations. Under pressure in a superheated steam atmosphere, yarn is given a “memory” of its twist. Autoclave heatsetting is a batch, not a continuous, method. (2) An apparatus for making polymer under heat and pressure.

Average pile density

The weight of pile yarn in a unit volume of carpet. It is expressed in ounces per cubic yard in the formula: Density = pile yarn Weight (in ounces per square yard) times 36 divided by pile Thickness or pile Height (in inches). Average pile density factors for commercial carpets range from 4200 to 8000.

Axminster

A weaving method that originated in the 18th century in Axminster, England. In this method, individual pile tufts are inserted from spools of colored yarns, making possible an almost endless variety of colors and geometric or floral patterns.

B

Back coating

An adhesive compound applied for the purpose of locking pile yarn tufts into a carpet backing, bonding a secondary backing to a primary backing, increasing the fabric body or stiffness, and increasing dimensional stability.

Backing

Materials comprising the back of the carpet, as opposed to the carpet pile or face.

- For tufted carpets: Primary backing

- For fusion-bonded carpets: Backing material for fusion-bonded carpet is a system of layered vinyl or plastic compound and fiberglass scrim for dimensional stability.

- For woven carpets: Backings of woven carpets are the “construction yarns” comprising chain warp, stuffer warp, and shot or fill, which are interwoven with the face yarn during carpet fabric formation.

Backing fabric

A fabric into which a pile yarn is inserted, or a reinforcing layer that is adhered to the reverse side of a fabric.

Backing systems

Conventional backing: Carpet with a primary and secondary latex-laminated woven or nonwoven fabric. Sometimes referred to as ActionBac®.

- Attached cushion: Padding, such as foam rubber or polyurethane, that is made as an integral part of the backing.

- Conventional backing: Carpet with a primary and secondary latex-laminated woven or nonwoven fabric. Sometimes referred to as ActionBac®.

- Thermoplastic: A molten resin process that permanently adheres the primary and secondary backing. This backing system is branded as Unibond®

- Unitary: A single lamination of fabric backing with high rubber content latex or hot-melt resin compound for increased tuft bind. Used primarily with loop pile carpet.

- Urethane (polyurethane): A polymeric resin applied by the carpet mill in the finishing process. In the heat and curing chamber it reacts and creates a foam-like texture. This backing encapsulates the yarn for extra tuft bind with a cushion attached.

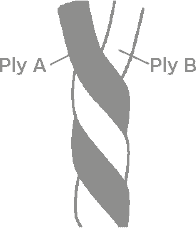

Barber-pole

Two different colors of yarn twisted together to form a two-ply yarn.

BCF yarn

An abbreviation for Bulked Continuous Filament yarn, referring to synthetic fibers in a continuous form. BCF yarn can be used in cut or loop pile construction.

Beam

A large cylinder on which carpet yarns, usually predyed, are wound prior to feeding onto tufting, weaving or fusion bonding equipment.

Beck dye

Dyeing of tufted greige carpet in a large vat of dye liquor. In this process, the carpet roll is sewn into a loop and then is continuously rotated and immersed in the heated vat for several hours. Most commonly used for cut pile carpet, it offers good custom color flexibility. See “Dye methods.”

Biocide

Product typically used to kill microorganisms.

Biodegradable

A material which can serve as a nutrient source for bacteria or fungi, and in the process is decomposed into basic molecular building blocks (e.g. carbon dioxide, water, and nitrogen oxides).

Black Water

Wastewater from toilets and urinals, which contains pathogens that must be neutralized before the water can be safely reused. After neutralization, black water is typically used for non-potable purposes, such as flushing or irrigation.

Bleeding

Loss of color by a fabric or yarn when immersed in water or a solvent, as a result of improper dyeing or the use of dyes of poor quality. Fabrics that bleed will stain white or lightly shaded fabrics that come in contact with them when wet.

Blend

A mixture of two or more fibers or yarns.

Blending

The mixing of staple fibers before they are carded, drafted and spun into yarn. Blending is done for consistency in the final yarn and is a critical step to avoid “streaks” in a carpet.

Boucle

(1) An uneven yarn of three plies, one of which forms loops at intervals. (2) A fabric made of boucle yarns and having a looped or knotted surface.

Broadloom

Denotes carpet tufted or woven in widths greater than six feet.

Bulking

Also known as crimping or texturizing. Bulking imparts texture/fullness to the fiber or yarn during production. Bulking is done to increase the coverage and bloom the yarn will have in the carpet face. Bulking also adds to fiber resiliency (“spring back”). See “Texture.”

C

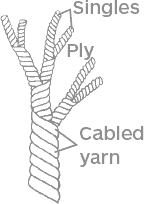

Cabled yarn

A yarn formed by twisting together two or more plied yarns.

Caprolactam

The single basic ingredient in the production of Type 6 nylon. Caprolactam has a chain of six carbon atoms. It is a petrochemical.

Carbon Dioxide

Odorless gas commonly sourced by respiration, and has been widely used as a measure of the ventilation adequacy of a space. A principle greenhouse gas. It is the result of the oxidation (including active combustion and respiration) of carbon based substances.

Carbon Monoxide

A colorless, odorless and highly toxic gas commonly created during combustion.

Carcinogen

Any substance capable of causing or aggravating cancer.

Carding

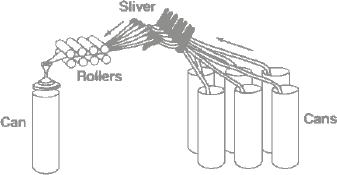

The step after blending in the staple spinning process which combs out the loose fibers and arranges them in orderly strands called sliver. Sliver is drawn and blended, then twisted and further drawn into yarns.

Cationic dyeable nylon

Nylon polymer that has been modified chemically to make the fiber receptive to cationic (basic) dyes. Cationic dyeable yarns are used in conjunction with acid dyeable yarns to produce multicolors in piece dye methods.

CFM

See “Cubic ft./min.”

Cleanability

The ability or degree that a stain is removed from a carpet.

Climate

The temperature, humidity, precipitation, winds, radiation, and other meteorological conditions characteristic of a locality or region over an extended period of time.

Closed-loop Process

Part of an industrial production process; not part of a waste management process. Materials reclaimed and returned in a closed-loop process are neither classified as, defined as, nor operate as, a waste, i.e., any discarded material. Materials in a closed-loop process are treated as commodities in a manner designed to avoid loss or release to the environment (See Electronic Code of Federal Regulations (e-CFR), 40 C.F.R. _ 261.4(a)(8)).

Closed-loop Recycling

A recycling system that uses a “closed-loop process.” See “closed-loop process”.

Color matching

The proper coordination of color and shade. Critical to color matching are: (1) The light under which the colors are compared. (The light source being used in the real conditions of the commercial environment should be used to match colors.) (2) The surface texture of the object being matched (cut pile carpet can appear darker than loop made of the same yarn). (3) The surface luster of the object being matched (higher yarn luster can look darker than lower luster fibers).

Colorfastness

The ability of a fiber or carpet to retain color when exposed to (1) ultraviolet light, (2) crocking (wet or dry) and (3) atmospheric conditions (according to manufacturers

Contaminant

Any physical, chemical, biological or radiological substance or matter that has an adverse effect on air, water or soil.

Contamination

Introduction into water, air and soil of microorganisms, chemicals, toxic substances, wastes or wastewater in a concentration that makes the medium unfit for its next intended use. Also applies to surfaces of objects, buildings, and various household and agricultural use products.

Continuous dyeing

Dyeing of carpet (greige) while it travels continuously through a dye range. The process is frequently referred to by the name of one of the prime machinery manufacturers, Eduard Kuster (pronounced “Kooster”). Continuous dyeing can produce multicolored or solid-colored carpet. Multicolored carpet is achieved by using yarns of varied dye affinity, or with various accessories that can give a pattern or overprint. Advantages include large dye lots, relatively low cost and color flexibility. However, this method is more critical than beck dyeing or yarn dyeing for side-to-side matching consistency (the carpet must be installed in roll sequence).

Continuous filament

Unbroken strand of synthetic fiber, such as filament nylon or olefin. Nylon and olefin are made by extruding molten polymer through a spinnerette (similar to a showerhead). The fibers are cooled, then stretched and textured into bundles referred to as yarn. This yarn can be plied or commingled with other yarn and then tufted.

Continuous heatsetting

The process of applying heat to yarns to “set” or retain bulk, twist and spring introduced by spinning and/or twisting. Continuous heatsetting can be applied to staple or continuous filament yarns. The two primary types of continuous heatsetting equipment are the Superba, which uses steam and pressure, and the Suessen, which uses dry heat. See “Heatsetting.”

Cradle-to-Cradle

Derived from the “Cradle-to-Grave” design methodology but ensures that end-of-life will result in materials that will become nutrients or feedstock for recycling into other valuable products.

Cradle-to-Grave

Design methodology that takes into account all stages of the life cycle (raw material extraction through end-of-life disposal) of a product, service, or building early in the design process.

Creel

The rack or frame located behind a tufting machine which holds the cones of pile yarn that feed into the needles of a tufting machine.

CRI (The Carpet and Rug Institute)

A national trade association representing the carpet and rug industry.

Crimp

In fiber, a nonlinear configuration, such as a sawtooth, zigzag or random curl relative to the fiber axis. Most synthetic fibers, both staple and filament, used in carpets are crimped. Fiber crimp increases bulk and cover and facilitates interlocking of staple fibers in spun yarns. See “Texture.”

Crocking

The removal of dye from a fabric by rubbing. Crocking can be caused by insufficient dye penetration or fixation, the use of improper dyes or dyeing methods, or insufficient washing and treatment after the dyeing operation. Crocking can occur under dry or wet conditions.

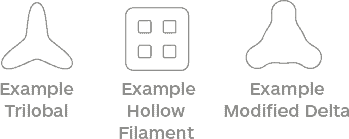

Cross section

The shape of a fiber when cut perpendicularly to its axis. Man-made fiber cross sections vary to produce a wide variety of physical effects such as soil-hiding characteristics, soil releasing, luster, and fineness or coarseness. Hollow filament fiber shapes are highly engineered and are among the most advanced filament cross sections. The delta is among the most advanced staple cross section.

Crushing

The collapsing of pile yarns, resulting in carpet matting and loss of resilience. This form of carpet failure usually occurs in the areas of heaviest traffic. It is also called “matting” and “walking out.” It can be minimized by the use of more resilient fibers, denser construction, and somewhat higher weight, and (in cut pile) higher tuft twist and proper heatsetting.

Cubic ft./min. (CFM)

Cubic feet per minute, a common measure of airflow.

Cushion-backed carpet

Carpet having a cushion, padding or underlay material as an integral part of its backing.

Cut and loop pile

Carpet whose face shows a pattern, either geometric or floral, made up of a combination of loop pile tufts and cut pile tufts. The carpet can be dyed solid or multicolored.

Cut pile

A pile surface created by cutting the loops of yarn in a tufted, woven or fusion-bonded carpet.

D

Delamination

A form of deterioration of tufted carpet in which the primary back and face yarns separate from the secondary back.

Deluster

To subdue or dull the natural luster of a textile material by chemical or physical means. The term often refers to the use of titanium dioxide or other white pigments used in textile materials.

Delustering

Synthetic fibers with polymer additives and/or cross section design modifications that limit its natural brightness or reflectivity. Delustering improves soil-hiding characteristics, as it limits the soil magnification that would occur with clear or shiny fiber.

Denier

A weight-per-unit-length measure of filament fibers or yarns. Denier is numerically equal to the weight in grams of 9,000 meters of fiber. Denier is a direct numbering system in which the lower numbers represent the finer sizes and the higher numbers the coarser sizes. In the U.S., the denier system is used for numbering filament yarns and man-made fiber staple (but not spun yarns). The following denier terms are in use:

Density

See “Average pile density.”

Design for Environment

An engineering perspective in which the environmentally related characteristics of a product, process, or facility design are optimized.

Differential dyeability

Fibers that have different dye affinities combined together to produce multicolor carpet from a single dyeing.

Dimensional stability

The ability of carpet to retain its size and shape once installed. Typically, dimensional stability is obtained in tufted carpet by the application of a secondary back. In woven carpet, dimensional stability is normally provided by choosing stable backing yarns, especially the stuffer and filling, as well as by application of latex to the completed carpet.

Dioxin

Typically defined as a class of similar chlorinated compounds that are persistent, bioaccumulative, and very toxic. Predominantly related to human activities _ manufacturing and incineration.

Downcycling

A term coined to disparagingly describe creation of a product of lesser intrinsic value manufactured from a material at the end of its service life, which had higher initial end use value; it is important to note that as the term downcycle has historically been used, it does not provide insight into environmental benefit (e.g. there may actually be more environmental benefit from extending the life of a complex polymer prior to energy recovery or taking it apart into its respective building blocks).

Drawing (third stage of nylon production)

(1) The process of fiber stretching to align molecules after extrusion. This process gives fibers greater tensile strength. This is done in synthetic fiber production after the molten fiber strands harden. (2) The process of pulling and thinning of sliver (combed staple fiber strands) in the spinning of staple yarn. Multiple ends of sliver are blended by feeding them through rollers at a slower speed than their uptake. This causes the fibers to be pulled or drawn and parallelized. The resultant finished sliver is ready to be spun into yarn.

Drop match

A drop match is a pattern that continues across the carpet diagonally or at a 45-degree angle to the edge of the seam.

Dye lot

A quantity of carpet dyed at one time or made from yarn dyed at one time which is consistent in color throughout the fabric.

Dye methods

- Beck dyed: A method of batch dyeing carpet. A piece dye method. The carpet is sewn into a loop, then hung on a large reel in the dye beck unit which moves the carpet through the dye liquor. This process is continued for a set time and achieves excellent color uniformity throughout the carpet.

- Continuous or “Kuster” dyed: A method of continuously dyeing carpet. A piece dye method. Kuster manufactures a continuous dye machine that is commonly used. Printing is another continuous dyeing process. Large lots of a single dye series are possible with continuous dyeing, but side-to-side color consistency should be verified.

- Continuous solid color dyed: A process of dyeing singles or plied yarn using dye rolls. The application of dye is similar to continuous space dye process except that a single color is applied to the yarn. These solid color yarns can be tufted into multicolored carpets.

- Package dyed: This is similar to skein dyeing in as much as undyed yarn is wound on perforated tubes and the packages are dyed by passing dye liquor through the packages under pressure.

- Pad dyed: A process of dyeing carpet, yarn or fiber stock continuously. The material to be dyed passes through a trough containing the dye liquor and then between heavy rollers that squeeze the dye liquor evenly into the material.

- Skein dyed: A method of dyeing yarn. Undyed spun or filament yarns are plied and heatset, then reeled into skein form and dyed in skein dye kettles.

- Solution dyed: Pigment is added to the molten polymer from which the filaments are made. The fiber is extruded in colored form.

- Space dyed: A method of dyeing yarn. Space dye refers to yarn with multiple colors printed on each strand. There are three basic processes used to create this effect: the warp system, the knit-de-knit process and the continuous dye process. (1) In the warp system, multiple strands of yarn are continuously printed at spaced intervals with different colors. These yarns usually have “long” spaces of each color. (2) In the knit-de-knit process, the yarn is first knitted into a tubular fabric (sock), then dyed to a solid color and then overprinted with up to seven different colors. These yarns usually have “short” spaces of color. (3) In the continuous dye process, yarn is dyed as singles or plied yarn and color is applied either by air jet or dye rolls. This process allows for yarns to have either long or short spaces of color.

- Stock dyed: Used for staple fiber only. Undyed, loose staple fibers are dyed in a vat. They are then blended, carded and spun into yarn.

Dye sites

Functional groups within a fiber that provide sites for chemical binding with the dye molecule. Dye sites may be either in the polymer chain or in chemical additives included in the fiber.

E

Exposure

Quantity of a substance or material that a living organism could ingest, inhale, or absorb from a given environment.

Extrusion (second stage of nylon production)

The process of forcing molten material through a spinnerette (similar to a showerhead). Once exposed to air cooling, the fiber strands harden. It is at the extrusion stage that many of the fiber engineering improvements take place: cross section design, shape, size and uniformity to give better soil hiding, soil releasing, and strength. All synthetic carpet fibers are extruded.

F

Face weight

The total weight of the face (above the backing) yarns in the carpet.

Fading

Loss of color caused by sunlight or artificial light, atmospheric gases including ozone, nitrogen dioxide and hydrogen sulphide, cleaning and bleaching chemicals such as sodium hypochlorite, and other household and industrial products. Commercial installations in areas where such exposures occur require care in selection of colorfast carpet.

Fading tests

Laboratory tests designed to predict the likelihood of carpet fading under actual use conditions. Fading is usually caused either by ultraviolet light or by exposure to ozone or nitrogen oxide gas. Carpet can be tested in laboratory for results against fading agents. Dye stuff, hue or fiber can affect fading. A specific carpet being considered for a critical installation should be tested prior to final selection.

Fiber

A unit of matter, either natural or man-made, that forms the basic element of fabrics. The term refers to units that can be spun into a yarn or felting and can be processed by weaving, tufting, knitting or fusion bonding. Important properties include elasticity, fineness, uniformity, durability, soil resistance, luster, and denier.

Fiber shape

Refers to the cross section and size of individual filaments. Fiber shape impacts soil hiding and soil release (cleanability). See “Cross section” and “Extrusion.”

Fiber size

Refers to the denier per filament (dpf) or thickness of a filament. Fiber size impacts soil-trapping and soil-releasing capabilities.

Filament

Fiber which has been extruded and is then converted into yarn fiber, staple or tow.

Filament count

The number of individual filaments that make up an extruded yarn fiber, staple or tow.

Filtration

The percolation of water through sand and other settled sediment to remove suspended particles.

Finishing

Processing of carpets after tufting (weaving) and dyeing is called finishing. Processes include application of secondary backing, application of attached foam cushion, application of soil-resistant treatment, shearing, brushing, dyeing, printing and others.

Flame resistance tests (also called “flammability tests”)

Procedures that have been developed for assessing the flame resistance of carpets. The most commonly accepted are:

- Methenamine Pill Test: A carpet flammability test described in federal regulations CPSC1-70 and CPSC 2-70. It measures the size of the burn hole produced by an ignited methenamine tablet under controlled conditions. Also used on the back of carpet. All carpet sold in the U.S. must pass the CPSC 1-70 flammability test.

- Radiant Panel Test: A test for the flammability of carpets or rugs in which the specimen is mounted on the floor of the test chamber and exposed to intense radiant heat from above. The rate of flame spread is assessed. (ASTM E-648 Class I .45 watts/cm; Class II .22 watts/cm.)

- Flame-resistant: A term used to describe a material that burns slowly or is self-extinguishing after removal of an external source of ignition. A fabric or yarn can be flame-resistant because of the innate properties of the fiber, the twist level of the yarn, the fabric construction, the presence of flame retardants or a combination of these factors.

Fluorochemical

Low-surface-energy technology used as a soil resistance treatment for carpet.

Fly Ash

The solid residue derived from incineration processes. Fly ash can be used as a substitute for portland cement in concrete.

Foot traffic units

One foot traffic unit is described as a pedestrian walking across a measured section of carpet, one time. Foot traffic is classified as follows (See individual traffic rating for details):

- Light Less than 100/day

- Moderate 100

- Heavy 1,000

- Extra Heavy More than 10,000/day

Frieze

A yarn that has been very tightly twisted to give a rough or nubby appearance to the finished carpet pile.

Fungicide

Pesticides that are used to control, deter or destroy fungi.

Fungus (Fungi)

Molds, mildews, yeasts, mushrooms and puffballs; a group of organisms that are lacking in chlorophyll and usually non-mobile, filamentous and multicellular. Some grow in soil; others attach themselves to decaying trees and other plants to obtain nutrients. Some are pathogens; others stabilize sewage and digest composted waste.

Fusion bonding

Fabrication of carpet for a 6

Fuzzing

A hairy effect on the carpet surface caused by fibers working loose under foot traffic or by slack yarn twist. This can be caused by poor latex penetration, poor yarn spinning, poor twisting and heatsetting, or improper maintenance. Not to be confused with initial shedding, a normal phenomenon associated with spun cut pile construction.

G

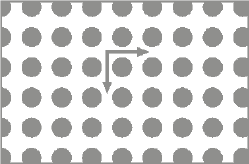

Gauge/pitch The number of ends of surface yarn counting across the width of carpet. In tufted carpet, gauge is the number of ends of surface yarn per inch counting across the carpet; e.g., 1/8 gauge = 8 ends per inch. In woven carpet, pitch is the number of ends of yarn in 27 inches of width; e.g., 216 pitch divided by 27 = 8 ends per inch. To convert gauge to pitch, multiply ends per inch by 27; e.g., 1/10 gauge is equivalent to 270 pitch, or 10 ends per inch.

Gray Water

Untreated or partially treated wastewater that is used for such purposes as watering lawns or flushing toilets (rather than using cleaner water of drinkable quality).

Green Buildings

Buildings in which environmental considerations are given to design, construction and operation.

Green Design

A design, usually architectural, conforming to environmentally sound principles of building, material and energy use. A green building, for example, might make use of solar panels, skylights and recycled building materials.

Greenwash

Disinformation disseminated by an organization so as to present an environmentally responsible public image.

Greige goods

(Pronounced “gray” goods.) Term designating carpet in an undyed or unfinished state.

H

Hand

How the carpet feels to the touch. Factors determining how the carpet feels include weight, stiffness, fiber type, dpf, density and backing.

Hazard

A material or condition that may cause damage, injury, or other harm, frequently established through standardized assays performed on biological systems or organisms. The confluence of hazard and exposure create a risk.

Hazardous Waste

Wastes that are particularly dangerous or destructive; specifically characterized by one or more of the following properties: ignitable, corrosive, reactive, or toxic.

Heather

A subtle multicolored effect produced by commingling (intermingling) yarns or spinning blended fibers of different colors together.

Heatsetting

Process for stabilization and setting a memory of twist in plied yarns. “Autoclave” treats skeins with pressurized steam in a batch operation. “Superba” uses conditions similar to the autoclave but it is a continuous process. “Suessen” is a continuous dry heatsetting method used most commonly for spun yarn heatsetting. See “Continuous heatsetting.”

Heavy Metals

Elements such as lead, mercury, zinc, copper, cadmium, and so forth, that may be required in trace amounts by organisms, but can cause damage when ingested in larger quantities.

Heavy traffic

1,000 to 10,000 traffics per day or up to 2,000,000 traffics for the life of the carpet. Could also include some directional, nondirectional and rolling traffic, as well as tracked-in dirt. See “Foot traffic units.”

Herbicide

A chemical substance used to kill plants.

Hexamethylene diamine

A chemical compound, with a chain of six carbon atoms, that is reacted with adipic acid to make Type 6,6 nylon. It is a petrochemical.

Hexapod drum test

An instrument to test pile floor coverings to produce changes in appearance and color due to changes in surface structure by mechanical action. This accelerated test, primarily used in Canada, provides a specific rating of the ability of the carpet to withstand crushing and matting.

Hollow filament fibers

Refers to filaments with interior voids. Hollow-core fibers improve the soil-hiding ability of nylon by diffusing light passing through the fiber. The diagram shown is one of the fiber shapes used for Antron® nylon.

Hydrocarbons (HC)

Chemical compounds that consist entirely of carbon and hydrogen.

Hydrophilic

Having a strong affinity for water; attracting, dissolving in or absorbing water.

Hydrophobic

Having a strong aversion to water; repelling water.

I

Indoor Air Quality (IAQ)

ASHRAE defines acceptable indoor air quality as air in which there are no known contaminants at harmful concentrations as determined by cognizant authorities and with which 80% or more people exposed do not express dissatisfaction.

J

Jute

A fibrous plant, native to India and Asia, which can be shredded and spun into yarn, used for backing in woven carpets, or itself woven into sheets and used as secondary backing on tufted carpet. In many applications, jute is being replaced by fiberglass, polypropylene or other synthetic fibers.

K

Knitting

A fabrication process comprised of interlacing yarns in a series of connected loops with needles. Some carpet is produced by knitting, but it is generally categorized as woven carpet. In carpet knitting, as in weaving, pile and backing are produced simultaneously. Multiple sets of needles interlace pile, backing and stitching yarns in one operation.

L

Latex

A water emulsion of synthetic rubber, natural rubber or other polymer. In carpet, latex is used for laminating secondary backings to tufted carpet, backcoating carpet and rugs, and for backcoating woven carpets and rugs. Almost all carpet latex consists of styrene-butadiene synthetic rubber (SBR) compounded with large quantities of powdered filler.

LEEDTM Rating System

LEED (Leadership in Energy and Environmental Design) is a self-assessing system designed for rating new and existing commercial, institutional, and high-rise residential buildings. It evaluates environmental performance from a “whole building” perspective over a building

Level loop pile

A woven or tufted carpet style having all tufts in a loop form and of substantially the same height.

Life Cycle Analysis (LCA)

An evaluation of the environmental effects of a product or activity holistically, by analyzing the entire life cycle of a particular material, process, product, technology, service, or activity. The life cycle assessment consists of three complimentary components _ inventory analysis, impact analysis, and improvement analysis _ together with an integrative procedure known as scooping.

Life Cycle Cost (LCC) Method

A technique of economic evaluation that sums

Light traffic

Less than 100 traffics per day. Could also include some directional traffic, but no tracked-in dirt. See “Foot traffic units.”

Lightfastness

The degree of resistance of dyed textile materials to the color-destroying influence of sunlight. Two methods of testing are in use: (1) Exposure to sunlight, either direct or under glass. (2) Accelerated laboratory testing in which several types of artificial light sources are used.

Loop pile

A tufted or woven carpet pile surface where the face yarns are comprised of uncut loops. Loop pile can be level, textured or multilevel.

Luster

Brightness or reflectivity of fibers, yarns, carpets or fabrics. Synthetic fibers are produced in various luster classifications including bright, semi-bright, semi-dull and mid-dull. The luster of finished carpet could also be influenced by yarn heatsetting methods, dyeing and finishing. In high-traffic commercial areas, duller carpet yarns are often preferred for soil-hiding ability.

M

Matting

See “Crushing.”

Melting point

The temperature at which a carpet fiber changes from a solid to a liquid.

Microbial Growth

The amplification or multiplication of microorganisms such as bacteria, algae, diatoms, plankton and fungi.

Microbiological Organism

Broad range of living organisms, which typically can be viewed only through a microscope.

Micron

A measure of length; one millionth of a meter.

Moderate traffic

100 to 1,000 traffics per day. Could also include some directional and nondirectional traffic, some pivoting and little tracked-in dirt. See “Foot traffic units.”

Modified delta cross section

An advanced fiber cross section engineered by INVISTA. The smooth delta shape hides soil and minimizes soil buildup more than trilobal cross sections. (The trilobal has deep crevices that trap soil particles.)

Modular carpet or tile

Also called “carpet tile.” Generally 18″ x 18″ squares cut from 6

Mold

Mold is a fungus that typically grows in a filamentous cobweb-like mass under damp conditions and is capable of producing staggering numbers of reproductive spores in as little as a few days. Molds are non-chlorophyll containing entities, which require organic matter, living or dead, for survival. Mold is a critical participant in the “recycling” of dead organic material on the planet. Molds are extraordinarily diverse in character and their relationship with humans span the positive (e.g., food, antibiotics) to the negative (e.g., pathogens, antigens, toxins).

Monofilament

A single filament of a man-made fiber usually of a denier higher than 14. Monofilaments are usually spun individually instead of through a spinnerette.

Multilevel loop pile

A woven or tufted carpet style having tufts of varying pile heights, resulting in a sculptured appearance, pattern or subtle shading. Today most multilevel loop styles are made on tufting machines equipped with servo motor controls. The servos allow for precise patterning and more exact yarn control/usage.

N

Nylon

A petrochemical-based fiber invented in 1938. There are two basic types of nylon used in the production of carpet: Type 6,6 nylon and Type 6 nylon. Nylon is produced in bulked continuous filament for use in loop carpets and cut pile carpets, and staple nylon that is spun into yarn for use in cut pile carpets. Nylon is the dominant fiber choice for commercial use due to its wear characteristics.

Nylon

Made from one base ingredient: caprolactam. Compared to Type 6,6 nylon, Type 6 nylon accepts dye at a faster rate. The more open molecular structure of Type 6 nylon allows dye stuffs (and stains) in more readily. Common spills and stains such as coffee, soda, foodstuffs and medicine will stain Type 6 nylon more readily than Type 6,6, whether solution dyed or conventionally dyed.

Nylon

Made with two base chemical ingredients: adipic acid and hexamethylene diamine. Type 6,6 nylon has a tighter molecular structure, making it more resilient and more resistant to stains than Type 6 nylon. In the U.S., where the highest commercial carpet standards are set, more than 60% of all nylon carpets specified are Type 6,6 nylon.

Nylon flake (or chip)

Polymer that has been cut into small pieces for storage or for immediate melting in the fiber extrusion process.

O

Off-Gassing

The emission of volatile organic compounds from synthetic and natural products.

Olefin fiber

Also known as polypropylene. It is used for molded items, sheets, films and fibers. Made from a by-product of gasoline refining, olefin has one ingredient: propylene. Since propylene is widely available at a comparatively lower cost than nylon base ingredients, olefin is less expensive than nylon. Olefin does not accept aqueous-based dyes or stains. Color is added in the manufacturing process in the form of pigment. Printable modifications are available but not extensively used. Olefin is a lightweight fiber and can have good bulk and cover. However, the polymer base creates a soft fiber that has poor resiliency, a lower melting point and poor texture retention as compared to nylon. The carpet fiber is available as bulked continuous filament yarn. Only when budget is the main consideration, lower life expectancy is anticipated and long-term appearance retention is not a priority, should olefin be considered.

Organic Compound

Vast array of substances typically characterized as principally carbon and hydrogen, but that may also contain oxygen, nitrogen and a variety of other elements as structural building blocks.

OSHA

Occupational and Safety Hazards Association.

Ozone (O3)

A naturally occurring, highly reactive, irritating gas comprising triatomic oxygen formed by recombination of oxygen in the presence of ultraviolet radiation. It forms a protective layer that shields the earth and its inhabitants from excessive exposure to damaging ultraviolet radiation. Ozone can also form in the lower atmosphere in the reaction of certain hydrocarbons, nitrogen oxides, air and light (smog formation).

Ozone fading

The fading of color from a dyed or pigmented fiber caused by atmospheric contaminants of ozone.

P

Particulates

Small aggregates of matter, in either a solid or a liquid state, that are larger than individual molecules and are one of the categories of air pollution.

Pathogens

Microorganisms (i.e. bacteria, viruses or parasites) that can cause disease in humans, animals and plants.

Pattern match

Lining up patterned carpet in such a way that the design element is continued across seams, making the finished installation appear cohesive. Patterns must be matched in the same way as they appear on the carpet itself, either in a set match or drop match. See “Set match” and “Drop match.”

Pattern streaks

Visually apparent streaking in patterned carpet resulting from linear juxtaposition of pattern elements in one direction. It is usually most visible in the length direction. It is not a carpet defect, but is inherent in certain designs. Contract specifiers should view rolls of carpet laid out on a floor to evaluate geometric or other busy patterns for this characteristic which may be objectionable in long corridors and other large areas, but not visible in small rooms.

Patterned loop

A woven or tufted carpet style having all tufts in a loop form in either a defined or random pattern and design.

Pesticide

Any chemical used for killing insects, weeds, etc.

Petroleum

Crude oil or any fraction thereof that is liquid under normal conditions of temperature and pressure. The term includes petroleum-based substances comprising a complex blend of hydrocarbons derived from crude oil through the process of separation, conversion, upgrading and finishing, such as motor fuel, jet oil, lubricants, petroleum solvents and used oil.

pH Scale

A logarithmic scale that is used to measure acidity; 1 is very acidic, 7 is neutral, and 14 is very basic (alkaline).

Photochemical Oxidants

Air pollutants formed by the action of sunlight on oxides of nitrogen and hydrocarbons.

Piece dyed

A method in which tufted carpet is dyed, as opposed to yarn dye methods in which color is added to yarn before tufting. See “Dye methods.”

Pigment

Highly colored, insoluble substance used to impart color to other materials. White pigments (e.g., titanium dioxide) are dispersed in fiber polymers to produce delustered (semi-dull and dull) fibers. Colored pigments are added to polymer to create producer colored or solution dyed yarns.

Pigmented yarns

Same as solution dyed yarns.

Pile

The visible surface of carpet, consisting of yarn tufts in loop and/or cut configuration. Sometimes called the face or nap.

Pile crush

Loss of pile thickness by compression and bending of tufts caused by foot traffic and heavy pressure from stationary furniture. The tufts collapse into the space between them. It may be irreversible if the yarn has inadequate resilience and/or the pile has insufficient density for the traffic load.

Pile height

The length of the tufts measured from the primary backing top surface to their tips. Pile tufts should be gently extended but not stretched during accurate measurement. This specification is expressed in fractions of an inch or decimal fractions of an inch in the U.S.

Pile reversal

A persistent change in the direction of the pile lay in certain areas resulting in an apparent visual difference of shade. Also known as watermarking, pooling or shading.

Pile thickness

The resulting thickness when the thickness of the backing is subtracted from the total thickness of the finished carpet.

Pile weight

The weight in ounces of the fiber in a square yard of carpet.

Pile yarn

The yarn making up the tufts of the carpet.

Pilling

The tendency of fibers to work loose from a surface and form balled or matted particles that remain attached to the surface of the carpet.

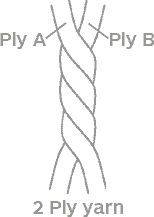

Ply

A measure of the number of individual yarns twisted together to produce the finished carpet yarn. For example, a two-ply yarn means that each tuft consists of two yarns twisted together. For cut-pile carpets, plied yarns must be heatset to prevent untwisting under foot traffic.

Polyester fiber

A synthetic fiber, usually produced with staple fiber and spun yarns, that is used in some carpet fiber.

Polymer

Polymers are large chemical molecules from which synthetic fibers are made. Polymers are complex, chain-like molecules made by uniting simpler molecules called monomers. Synthetic polymers used for commercial carpet fiber include Type 6,6 nylon and Type 6 nylon (polyamides) and polypropylene.

Polymerization (first stage of nylon production)

A chemical reaction where small molecules combine to form much larger molecules.

Polypropylene

See “Olefin fiber.”

Post-consumer Recycle Content

A product composition that contains some percentage of material that has been reclaimed from the same or another end use at the end of its former, useful life.

Post-dyed

Carpet that has been dyed in its tufted form. Post-dyed means the carpet, rather than the yarn, has been dyed.

Post-industrial Recycle Content

A product composition that contains some percentage of manufacturing waste material that has been reclaimed from a process generating the same or a similar product. Also called pre-consumer recycle content.

ppb

Parts per billion.

ppm

Parts per million.

Pre-dyed

Carpet that has been constructed with colored yarns either by solution dyeing or yarn dyeing.

Primary backing

See “Backing systems.”

Printed carpet

Carpet having printed colored patterns. Printing methods include flatbed screen printing, rotary screen printing and modern computer programmed jet injection printing.

Q

R

Reclamation

Restoration of materials found in the waste stream to a beneficial use that may be other than the original use.

Recyclable

Commonly referred to as the ability of a product or material to be recovered from, or otherwise diverted from, the solid waste stream for the purposes of recycling. FTC guidelines indicate that a product may not be advertised as “recyclable” unless a viable, active reclamation system exists, that is available to a majority of end users, and collects and processes the product for recycling.

Recycled Content

Materials that have been recovered or otherwise diverted from the solid waste stream, either during the manufacturing process (pre-consumer), or after consumer use (post-consumer). Pre-consumer material does not include materials normally reused by industry within the original manufacturing process.

Recycling

Process by which materials that would otherwise become solid waste are collected, separated or processed and returned to the economic mainstream to be reused in the form of raw materials or finished goods.

Red 40 Stain Scale

A standard comparison to rate degrees of Red Dye 40 staining from 10 (no staining) to 1 (severe staining).

Relative Humidity (RH)

Ratio of the amount of water vapor in air at a specific temperature to the maximum capacity of the air at that temperature.

Remediation

Efforts to counteract some or all of the effects of pollution after it has been released into an environment.

Renewable Resources

A resource that can be replenished at a rate equal to or greater than its rate of depletion (i.e. solar, wind, geothermal and biomass resources).

Repeat

The distance from a point in a design in a patterned carpet to a point where the identical pattern appears again, measured lengthwise and widthwise in the carpet. In matching the pattern, there will inevitably be some waste of carpet in order to obtain the best possible side match

Resilience

The ability of carpet to spring back to its original texture and thickness after being walked on or compressed by the weight of furniture. Also known as “resiliency.”

Respirable

Particles or aerosols capable of being inhaled into the deep lung, <3 microns in diameter.

Rows or wires

In woven carpet, this is the number of pile yarn tufts per running inch lengthwise. Called rows in Axminster and wires in Wilton and Velvet carpet. Analogous to “stitches per inch” in tufted carpet.

S

Sanitary Sewers

Underground pipes that carry off only domestic or industrial waste, but not storm water.

Saxony

A cut-pile carpet texture consisting of plied, heat-set yarns in a relatively dense, erect configuration, with well defined individual tuft tips.

Secondary backing

See “Backing systems.”

Selvage

The edge of the carpet. Most commercial carpets are shipped with the selvage on. Residential carpet is usually trimmed to the face yarn.

Set match

Refers to a pattern in a carpet which continues straight across the installed carpet at right angles to the seams.

Shading

Apparent color shade difference between areas of the same carpet caused by normal wear and/or random difference in pile lay direction. It is a characteristic of cut pile carpet. It is not a manufacturing defect.

Shearing

Finishing process in cut pile carpet manufacturing to create a smooth carpet face. The shearing process can also be used to create texture, as in random shearing. See “Tip shearing.”

Sick Building Syndrome (SBS)

(1) A human health condition in which infections linger, caused by exposure to contaminants within a building as a result of poor ventilation. (2) Building whose occupants experience acute health and/or comfort effects that appear to be linked to time spent therein, but where no specific illness or cause can be identified. Complaints may be localized in a particular room or zone, or may spread throughout the building and may abate on leaving the building.

Singles yarn

One yarn end of either continuous filament yarn or spun yarn. Singles yarn is most often plied, twisted, or air-entangled with additional singles yarns to create a “two-ply,” “three-ply” or “four-ply” yarn bundle.

Skein dyed yarn

Singles yarn that has been skein dyed. Yarn is wound in skeins and dyed in dye vats. This method yields small to mid-sized dye lots, but has custom color advantages. See “Dye methods.”

Sliver

An intermediate stage in the production of spun yarns from staple fiber. It is a large, soft, untwisted strand or rope of fibers produced by carding or pin drafting.

Soil hiding

The ability of a fiber to mask the presence of soil.

Soil resistance

The ability of a carpet fiber to resist dry soil and maintain its original appearance after intermittent or restorative cleanings.

Solution dyed

See “Dye methods.”

Space dyed

See “Dye methods.”

Spinnerette

The device (similar to a showerhead) that forms strands of filament as molten polymer is pumped through. It is at this stage that the fiber cross section, fiber size and the number of filaments in a yarn bundle (for continuous filament) are determined.

Spinning

The conversion of staple fiber into spun yarn.

Spun yarn

Yarn that is made up of short lengths of fiber, either synthetic staple or natural fiber.

Stain resistance

The ability of a carpet fiber to resist the absorption of stain and maintain its original appearance. For carpets to resist stains, some manufacturers use a topical stain-resist treatment that may be removed after hot water extraction.

Staple fiber

Also called staple. Short lengths of fiber which have been chopped from continuous filament in lengths of 4″ to 71

Static control

See “Antistatic properties.”

Static shock

Buildup of electrostatic energy on a carpet and the subsequent discharge to a conductive ground such as a file cabinet. Various static control conductive systems are used in commercial carpet to dissipate static charge before it builds to the human sensitivity threshold, which is 3.5kV.

Sterilizer

One of three groups of antimicrobials registered by the EPA for public health uses. The EPA considers an antimicrobial to be a sterilizer when it destroys or eliminates all forms of bacteria, viruses, and fungi and their spores. Because spores are considered the most difficult form of microorganism to destroy, the EPA considers the term “sporicide” to be synonymous with “sterilizer.”

Stitches per inch (SPI)

Number of yarn tufts per running inch along the length of the carpet (as opposed to the gauge, which is the number of stitches across the width of the carpet).

Stock dyed

See “Dye methods.”

Suessen

A trade name of a German manufacturing company and its continuous heatsetting process. In Suessen setting, dry heat is applied to twisted yarn. The heat builds bulk and locks twist into the thermoplastic fiber

Superba

A trade name of a French manufacturing company and its continuous heatsetting process. In Superba setting, steam and pressure are applied to twisted yarn. Heat and pressure are applied to build the bulk and lock twist into the thermoplastic fiber

Surface area

The perimeter of an individual fiber filament or multiple filaments.

Surface energy

Technical measure of the tendency of a surface

Sustainability

Practices that would ensure the continued viability of a product or practice well into the future.

Sustainable

Meeting the needs of the present without compromising the ability of future generations to meet their needs.

Synthetic fiber

Produced by man-made means, not available in nature in the same form.

T

Tensile strength

The strength along the length of a fiber.

Texture

Visual and tactile surface characteristics of carpet pile, including such aesthetic and structural elements as high-low and cut and loop patterning, yarn twist, pile erectness or layover, harshness or softness to the touch, luster, and yarn dimensions.

Textured loop

A woven or tufted carpet style having all tufts in a loop form, usually with two or three pile heights. There is generally less difference between the lowest and highest pile heights than would be found in a multilevel loop carpet.

Tip sheared carpet

A textured loop pile carpet that has been sheared to create a cut and loop appearance.

Tip shearing

Shaving off tufted high loops in the finishing process to create a cut and loop texture or pattern.

Toxic

Capable of having an adverse effect on an organism; poisonous; harmful or deadly.

Tuft

A cluster of yarns drawn through a fabric and projecting from the surface in the form of cut yarns or loops. See also “Cut pile,” “Cut and loop pile,” “Level loop pile,” “Loop pile” and “Multilevel loop pile.”

Tuft bind

The force (usually measured in pounds) required to pull a tuft from the carpet backing. Also known as tuft lock. For loop pile, ASTM Method D1335 (tuft bind test) should result in a minimum 10-lb. average. For cut pile, ASTM Method D1335 (tuft bind test) should result in a minimum 5-lb. average.

Tufted carpet

Carpet produced by a tufting machine instead of a loom.

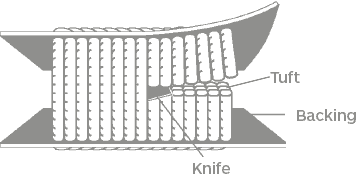

Tufting

A method of carpet manufacture in which surface yarns are sewn or “punched” through a primary backing material. The needles of the tufting machine form loops that are hooked by loopers on the underside of the backing material and which remain loops in level or textured loop carpet. Alternatively, the loops are tufted and cut with knives to create cut pile carpet. The tufted fabric is then coated with an adhesive to adhere a secondary back to provide durability and stability. In the past 5-7 years there have been significant advances in tufting technology, allowing for more intricate patterns and textures.

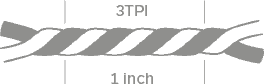

Turns per inch (TPI)

The number of times two or more yarns have been plied in an inch length. Also known as input ply twist. Most carpet yarns have 3.5 to 6.0 TPI.

Turns per tuft (TPT)

The number of twists in the pile yarn above the primary backing. A more accurate way of measuring relative twist level in cut pile carpets. Generally, the greater the turns per tuft, the better the performance.

TVOC

Total Volatile Organic Compounds.

Twist

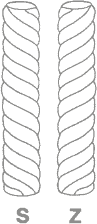

A yarn term describing the number of turns per inch and direction of twist of either the singles or plies around their axes. Twist direction is either right- or left-handed, also called “Z” or “S” twist. Most carpet yarns have 3.5 to 6.0 TPI. The performance of a cut pile carpet is dependent on the twist in the pile yarn. Spun yarns need more twist than filament yarns for good performance. For moderate or heavy commercial use cut pile, it is suggested that continuous filament have a minimum of 4.50 TPI while spun yarns have a minimum ply twist of 4.75 TPI.

Two-ply

Most common yarn ply. Two single yarns are twisted together, then heatset to maintain their twisted configuration. Can be used in either cut or loop pile carpet.

U

Unitary

See “Backing systems.”

Urethane

See “Backing systems.”

USGBC (U.S. Green Building Council)

The United States foremost coalition of leaders from across the building industry working to promote buildings that are environmentally responsible, profitable, and healthy places to live and work.

V

Velvet carpet

Woven carpet made on a loom similar to a Wilton loom but lacking the jacquard mechanism. Velvet carpets are generally level loop, level cut/loop or plush, in solid or tweed colors.

Ventilation

Process by which outside air is conveyed to an indoor space.

Vettermann drum test

An instrument to test pile floor coverings to produce changes in appearance and color due to changes in surface structure by mechanical action. This accelerated test, primarily used in the U.S., provides a specific rating of the ability of the carpet to withstand crushing and matting.

Vinyl

Colloquial term for the synthetic polymer, polyvinyl chloride. Also called PVC. PVC is used as a carpet back-coating for carpet tiles and 6

Volatile Organic Compound (VOC)

Organic substances capable of entering the gas phase from either a liquid or solid form.

W

Warp

A weaving term for yarns in woven fabrics and carpets that run in the machine direction (or lengthwise). Warp yarns are usually delivered to a weaving loom from a beam mounted behind the loom. Woven carpets usually have three sets of warp yarns, which may be wound on three loom beams. These include stuffer warp for lengthwise strength and stiffness; pile warp, which forms the carpet surface tufts; and chain warp, which interlaces with fill yarn to lock the structure together.

Watermarking

Irregular random shading or pile reversal in cut pile carpet. Although much research has been done in an effort to determine the cause for watermarking, there has never been a single or consistent reason determined.

Weaving

The original method for manufacturing carpet. In the weaving process, backing yarns are woven into a durable fabric while, simultaneously, face yarns are looped over wires and interlocked in the woven back. See “Axminster” and “Wilton.”

Weft

Yarns which run widthwise in woven carpet interlacing with various warp yarns.

Wilton

A type of woven carpet and the loom used to manufacture it. Wilton looms have jacquard pattern mechanisms which use punched cards/computer programs to select yarn color. The carpets are often patterned or have multilevel surfaces.

Wires

Parts of carpet weaving looms composed of thin metal rods or blades on which the pile tufts are formed. Round wires and cut wires are identical in shape. The cut wire has a small knife blade at the end and, as it is withdrawn, it cuts the yarn looped over it to form cut pile.

Wool

The original carpet fiber. Wool is noted for its excellent dyeability, luxurious feel and relatively high cost.

Woolen spinning

Spinning method which produces bulky, hairy yarn, usually used for wool yarns. A series of cards, or large cylinders with comb-like teeth, straighten the fibers into a paralleled fiber webbing. This webbing is blended with other webbing, then spun into yarn.

Woven backing

A tufted carpet term for primary or secondary backing manufactured by the weaving process. Secondary backings are usually woven jute or woven polypropylene.

Woven carpet

Carpet produced on a loom. Warp pile yarns intertwine with wires and backing yarns called warp yarns. These yarns are locked in with the weft yarns. Warp stuffer yarns are included to provide extra stability. Weaving is a slower, more expensive, labor-intensive fabrication method than tufting. Woven carpet is distinguished by intricate patterns and tailored, controlled textures.

X

Y

Yarn construction

An indication of the number of singles yarns combined to form a plied or heathered yarn.

Yarn count

A number used to describe the size of the yarn. Denier is used for BCF yarns, and cotton count for spun yarns.

Yarn dyeing

Applying color to yarns that are later used in making carpet. It can be in continuous yarn dyeing methods such as space dyeing or batch methods such as skein dyeing.

Yarn ply

See “Ply.”

Yarn size

The weight measure of the total bundle of filaments making up a yarn that indicates if the yarn is fine or coarse. Continuous filament yarns are sized by the denier or decitex system. Spun yarns are sized by the cotton count system. See “Denier” or “Cotton count.”

Yarn weight

Total amount of yarn used in the manufacturing of carpet. It is measured in ounces per square yard.

Z

Zippering

A loop pile carpet in which tufts are pulled from the backing resulting in long, lengthwise pulls out of the carpet. Zippering occurs when the tuft base is not securely encapsulated by the backing compound.